Continental Fortress XP fabric-reinforced conveyor belts are designed to withstand high abuse applications in a wide range of industries:

- Aggregate quarries

- Cement production

- Coal mining

- Foundries

- Hard rock mining

- Pulp and paper production

- Steel production

- Wood production

Exceptional resistance to rips, tears, and impacts make Continental Fortress XP industrial conveyor belts perfect for the most demanding applications:

- Log debarkers

- Log decks

- Mainlines

- Pit belts

- Primary crushers

- Secondary crushers

- Ship unloaders

- Trash and recycling

- Any high abuse application

Learn more about Continental Fortress XP fabric-reinforced conveyor belts and our other conveyance solutions:

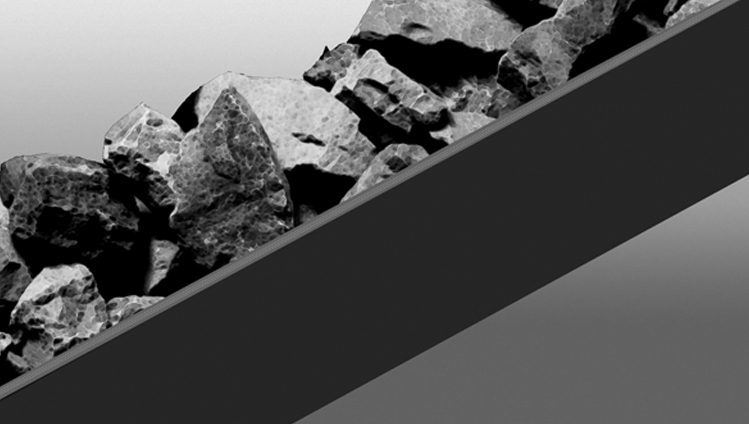

Because of their ability to withstand extremely heavy, sharp, and abrasive material, Fortress XP industrial conveyor belts are used to move aggregate, sand, and gravel at quarries. Likewise, the cement industry requires conveyor belts that will withstand highly abrasive material and hot temperatures, and again Fortress XP conveyor belts meet the requirements.

In coal, hard rock, and other mining operations, conveyor belts are used to transport raw materials quickly over long distances. Continental Fortress XP conveyor belts can be configured to meet the long distance needs of the largest mining operations.

Steel production requires strong, high-quality conveyor belts and that’s what’s made Fortress XP a top choice. In wood production conveyor belts must withstand the weight and impact of logs and other timber-based products, and Fortress XP conveyor belt technology is up to the challenge.

Continental Fortress XP Conveyor Belts Features & Benefits:

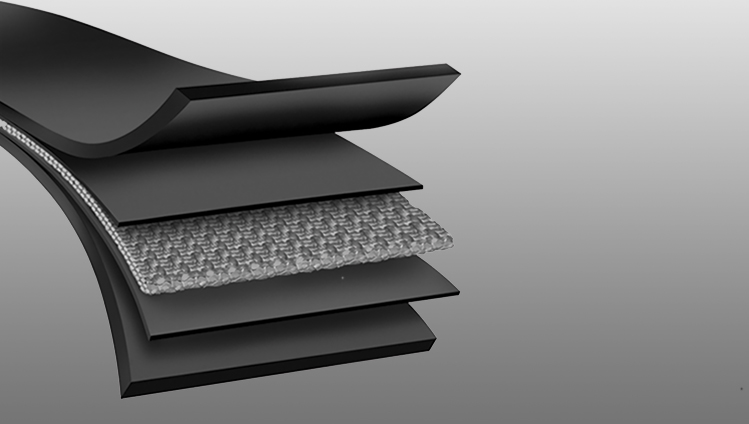

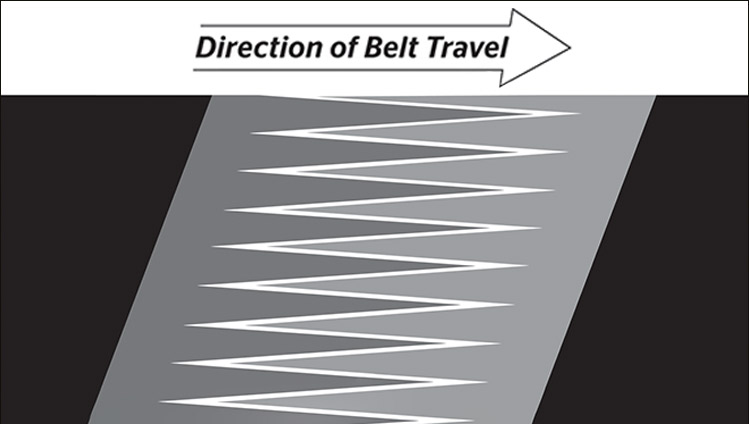

Innovative fabric weave

A dual-layer twill fabric gives Fortress XP industrial conveyor belts best-in-class load bearing and impact resistance.

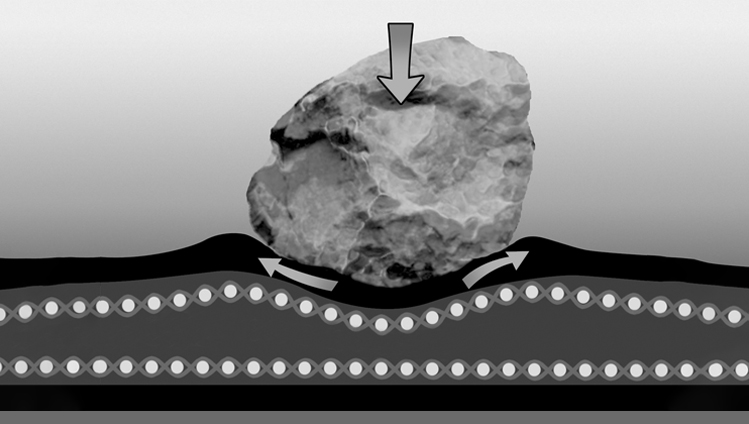

Exceptional impact resistance

Fortress XP has industry-leading impact resistance. Loading point impact damage can be a major cause of belt failure. Design engineers used an enhanced Dynamic Impact Tester to simulate loading impact force and its effects on belting.

High transverse tear strength

The dual-layer twill fabric design enables high transverse tear strength. This minimizes tears that result from material punctures as well as edge tears from misaligned belts.

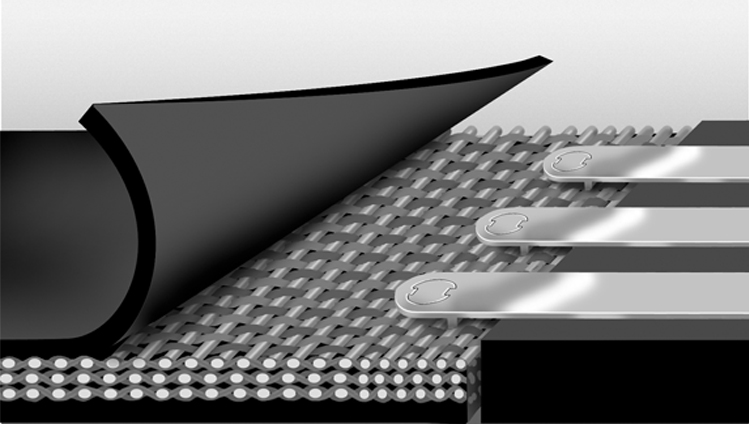

Superior rip resistance

Scrap metal or debris often get “hung up” in the structure of the conveyor, causing equipment damage and slits or cuts in long sections of the belt. Our fabric design helps dislodge and expel foreign objects and contains rips to a small area.

Enhanced mechanical fastener pull-out resistance

Rigorous dynamic and static testing means that Fortress XP belts will provide superior mechanical fastener retention as compared with multi-ply and straight-warp constructions.

Vulcanized finger splice

A full carcass finger vulcanized splice is recommended for Fortress XP belting. This splice method takes advantage of the superior strength properties of the Fortress XP carcass to retain 100% of the rated belt tension when splicing.

Sign up for more information or contact a member our customer support teams

Continental provides the highest quality conveyer belts for industrial applications, backed by expert sales, customers support, and technical teams to help ensure your applications have the right belt for the job.